發佈日期:2022-06-24 瀏覽:754

The five-day Print China 2023 concluded successfully on April 15th, attracting nearly 190,000 visitors. AFSystems made a strong presence at the event, showcasing a new logo and receiving enthusiastic responses from guests. The high interest in intelligent post-printing products bolstered our confidence in facing future challenges. Our commitment to "Union, Enhancement, Innovation" remains steadfast, empowering domestic customers with top-notch post-press solutions.

At the heart of AFSystems's booth was the "CABS 4000V hybrid perfect binding production system," positioned as the centerpiece. Integrating the AFC-744 folding machine and the CBF-SB loose sheet feeding device, the CABS 4000V effortlessly handles the B2 format signature folding, perfect binder finishing, and loose-leaf book block production. Paired with the SB-09V and HT-1000V for binding and cutting, respectively, this production system offers remarkable flexibility and scalability, providing users with an impressive production experience.

Beyond on-site demonstrations, the CABS 4000V can be combined with the MG-600 collating station to create a perfect binding production line for traditional offset printing sheets. Additionally, the combination of MG-600 and SB-17 gives birth to the CABS 6000 perfect binding production system, capable of handling 6,000 processes per hour. Targeted at medium to long-form product orders, the CABS 6000 operates efficiently with minimal labor, reducing overall production costs.

Debuting at PRINT CHINA 2023 with a fresh image, AFSystems presented the latest post-press technology and solutions. In the smart booklet area, the new "iCE STITCHLINER MARK Ⅳ" offers enhanced features, including the iCE LiNK port for simplified production management. The "dynamic riding ordering" function allows variable production, and the MARK Ⅳ, exhibited with a HOF-400 digital high-speed paper feeding device, ensures an improved production experience.

Adjacent to MARK Ⅳ is the FOLDLINER solution, consisting of the STITCHLINER 6000 saddle stitching line and the AFC-784 folding machine. This system streamlines production from offset printing sheets to saddle-stitched finished products, minimizing manual intervention and improving efficiency.

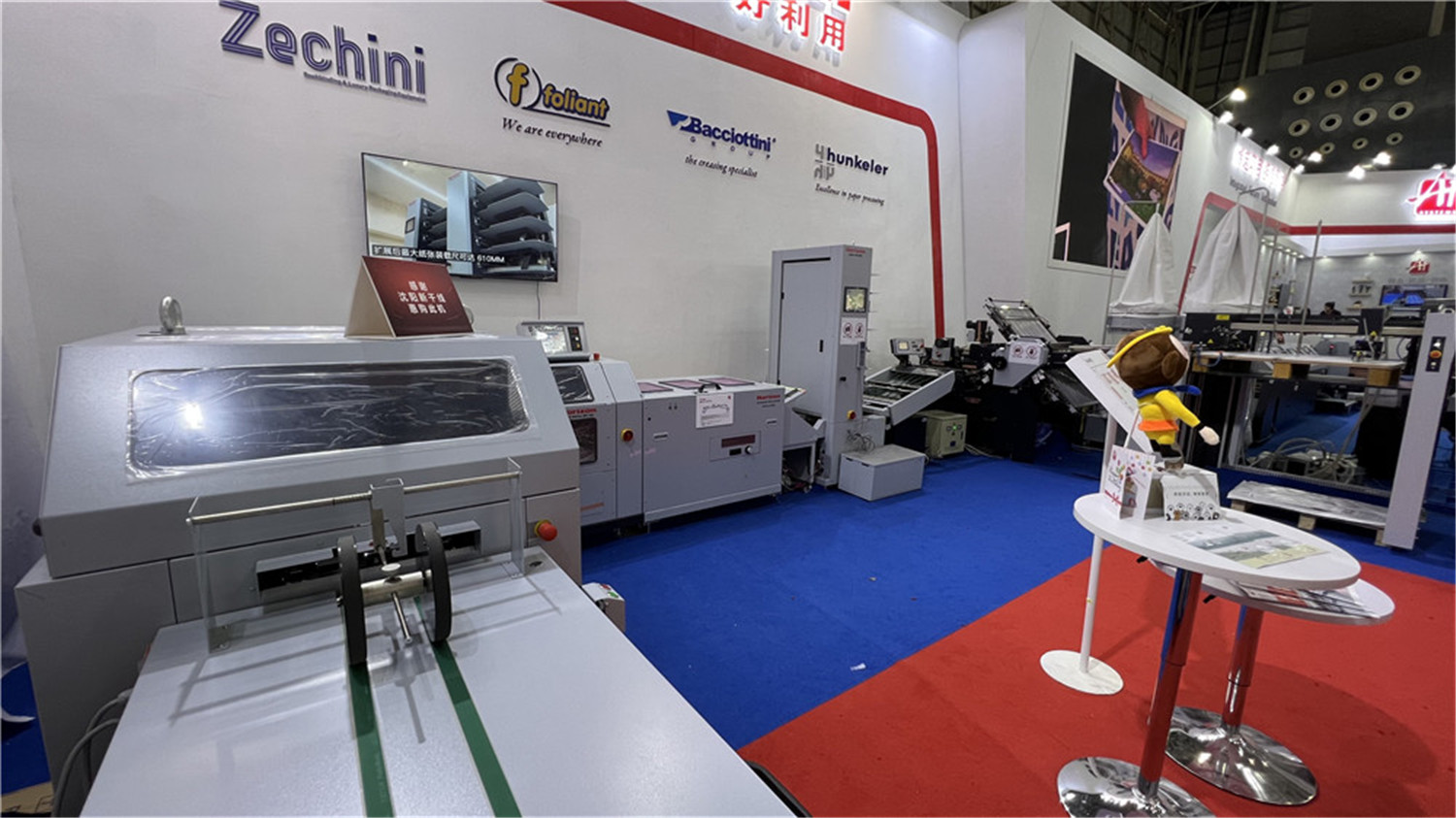

The hardcover production area showcases a comprehensive process using Horizon and Zechini post-press equipment. Horizon handles book block, ring lining, cover gluing, and cutting, while Zechini manages leather shell processing, ring lining, upper leather shell, and compaction molding. Supporting the hardcover process, the BQ-500 and HT-300 provide short-run personalized glue-bound book production, including unique A5 "pizza books" that captivated visitors.

In the environmentally friendly production area, AFSystems introduced the TKN-9 Japanese paper binding machine. Compact and eco-conscious, it utilizes special Japanese craftsmanship and "water guide wire" technology for safe processing. Demonstrating a production sample, AFSystems showcased an original cartoon "Cat home and Dog house" mini notebook, emphasizing the machine's versatility and eco-friendly approach.

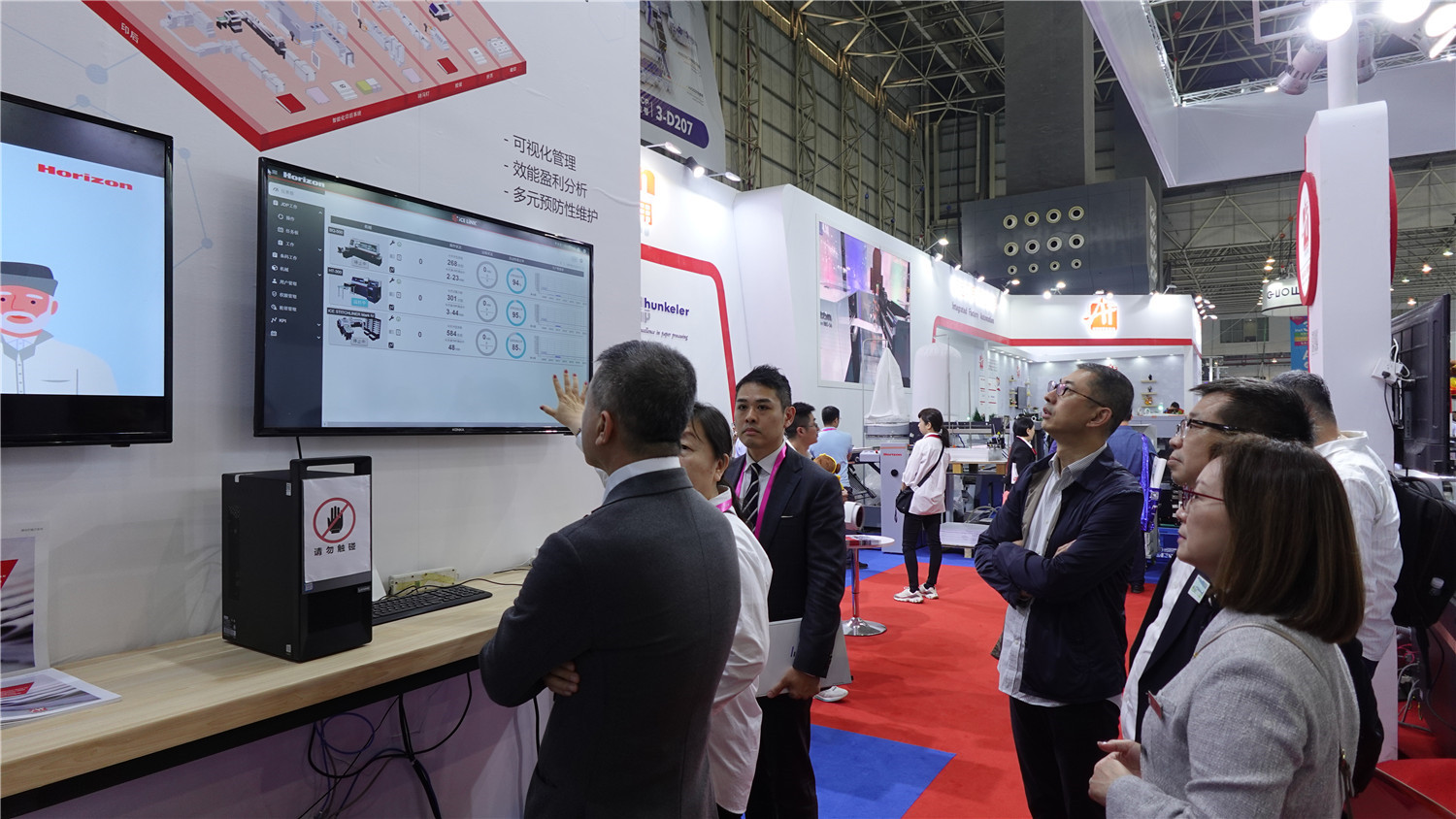

The booth also highlighted the "iCE LiNK" post-press production system by Horizon, connecting three sets of equipment: "iCE STITCHLINER MARK Ⅳ, iCE BINDER BQ-500, and iCE Trimmer HT-300." This system provides real-time information on equipment operation, production status, and efficiency analysis, enabling production managers to optimize processes effectively.

Since 2016, AFSystems has pursued the motto of "infinite technology, infinite possibilities," collaborating with customers to explore the domestic printing market. In the future,AFSystems will concentrate on presenting complete "systems," encompassing solutions and service teams. As the printing industry evolves, AFSystems aims to convey the theme of "Union, Enhancement, Innovation" through the concept of 'system,' creating a new paradigm for industry development.