發佈日期:2022-08-03 瀏覽:1876

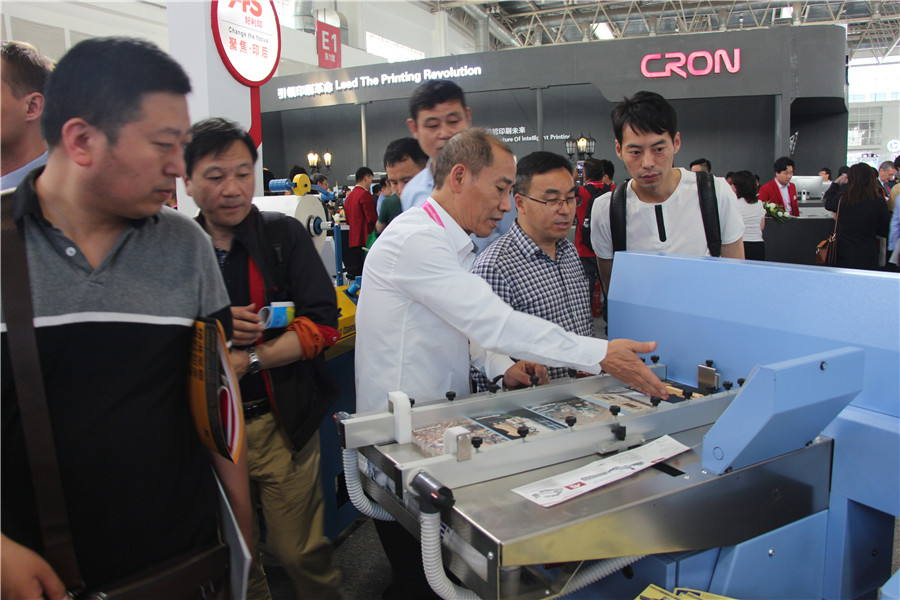

The 5-day international printing event China Print 2017 came to an end last weekend. The main equipment exhibited by AFS at this time includes saddle stitching, folding, glue binding, cutting, punching, pressing A variety of post-press equipment such as marks, laminations, epithelial shells, etc., the guests who came to visit unanimously gave a very high evaluation, and praised the AFS exhibition equipment for its extremely high intelligence and automatic high-efficiency performance!

The RD-4055 die-cutting machine is placed at the entrance of the booth. It is equipped with two blades of different heights to perform die-cutting work at the same time. The maximum speed can reach 6000/times per hour. Applied to improve the recycling of molds, a single process can be reused 5 times.

RD-4055 exhibited the finished AFS little penguin keychain and was warmly welcomed by many visitors. AFS supplies nearly 100 keychains every day, which shows the superb production quality of RD-4055!

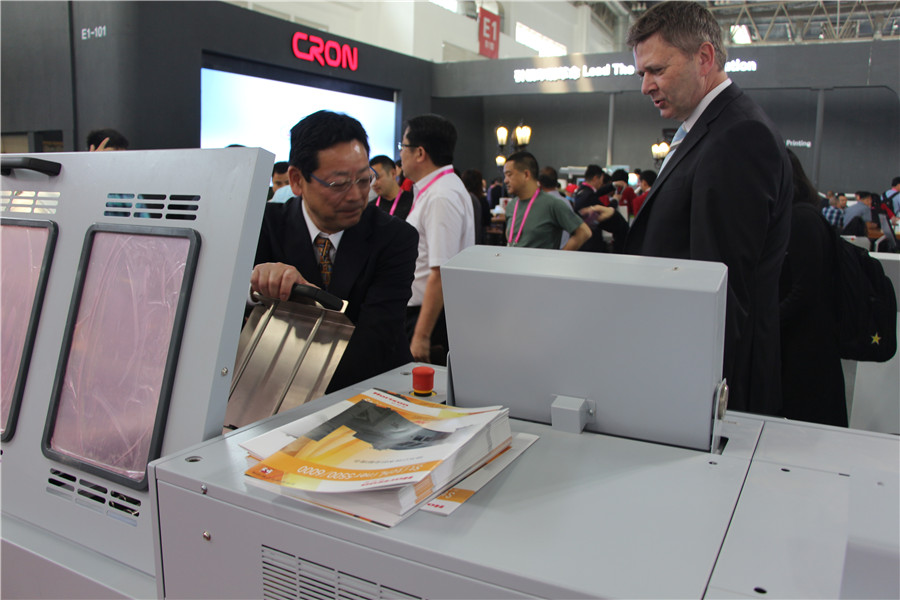

BQ-480+HT-80 perfect binding machine and cutting machine is a fully automatic production line, all settings including gluing and extruder height are automatically set according to the thickness of the book, plus SS-80 stacking books device, as well as a cooling conveyor, the operator can change the EVA or PUR plastic box according to the needs to produce high-quality books.

AFC-566AKT is a fully automatic folding machine, which is suitable for various folding methods. The color touch screen has preset 17 folding types and stores 200 jobs, covering almost all folding requirements of business and books.

Small, convenient, easy to operate, not losing the production performance of large models, the EF-35SR compact design incorporates a new air suction feeding system, which can load paper when folding to achieve uninterrupted production, EF-35SR also Equipped with preset counters for job tracking and batch counting.

The upgraded version of the StitchLiner6000C and the FolderLiner are the newly unveiled saddle stitching linkages. The upgraded version of the StitchLiner6000C is equipped with a three-in-one saddle stitching linkage with automatic page collection, creasing, saddle stitching and three-sided knife, up to 6000 Books/hour, the preferred linkage for short-run commercial rides. FolderLiner adopts a new and unique book binding system on the market, a hybrid system of folding and saddle stitching, and a PFU paper feeding device, which will greatly improve the production efficiency.

In addition to Horizon's post-press equipment, the Foliant, Zechini and Bacciottini exhibited this time also attracted the attention of many visitors. As the leaders of European post-press equipment, the shock they brought was very big.

Foliant's vega 400 A is a new, easy-to-operate, compact industrial laminator. Equipped with a non-stick pressure roller and a dual de-wrinkle bar and overlapping system that can be adjusted simultaneously, it can be used with both heavy-duty digital production and conventional product laminators.

The Roby Junior 2 brought by Zechini is a compact, multi-functional semi-automatic leather casing machine, mainly for the production of short and medium-sized leather casings.

Bacciottini's representative work DG Line 8000". DG Line 8000 is mainly suitable for indentation of on-demand printing and digital printing, with high precision and strong professionalism. The minimum indentation distance can reach 0.1mm, and the working paper can support 50 X70cm (max). ~8X10cm (min), can complete up to 8000 sheets of production per hour.